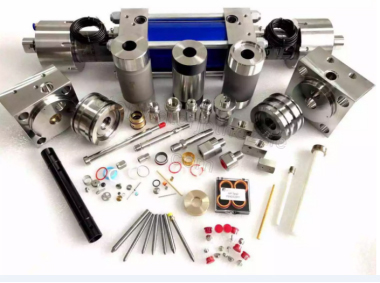

Three Commonly Used Consumables For Waterjets

Water jet is a large-scale equipment in the cutting field, which has many advantages. However, due to the high pressure and friction during the cutting process, there are also some consumables in use. So besides waterjet sand garnet, what other common...

Waterjets can cut just about any material that can be made into a sheet and placed in front of them. The most popular materials are metals (especially aluminum, because it's relatively soft and cuts quickly), because waterjets can cut very complicated shapes to a high precision...

What's the material of the front mixed abrasive waterjet cutting nozzle

At this stage, the main materials for manufacturing nozzles in my country are: diamond, gemstones, ceramics, cemented carbide, high-grade stainless steel and high-quality carbon steel. The pre-mixed type generally uses jewel nozzles...

What's the difference between Ruby nozzles in a water jet?

The reason why the water jet cutter has strong cutting ability is closely related to the nozzle it is equipped with. Compared with the ruby nozzle, its performance is obviously better. How much do you know about it? I'd like to share it with you...

Influence of nozzle of water jet cutter on cutting effect

Ultra high pressure water jet can cut all kinds of hard materials: stainless steel, aluminum, copper, steel, marble, glass, plastic, ceramics, tile and all kinds of visible materials. The precision of water jet cutting: the precision of cutting workpiece is between 0.1mm...

Research On Water Cutting Nozzle

Industrial ruby is a single crystal of alumina, its shape is half pear shape, first of all, it is cut by water. The gemstone is glued to the glass with the mixture of epoxy resin and PPTA (mass ratio 1:1.5) (shellac is used for gluing), and sliced, sliced and broken on the water cutting...