What's the performance of water cutting machine?

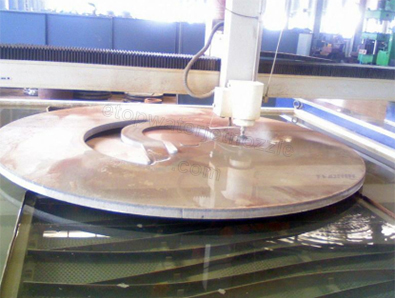

When the water cutting machine is used, the normal pressure water should be increased to more than 200 MPa through the supercharger, and then the pressure energy of water should be converted into kinetic energy through the small hole of an energy converter...

How to control the cutting accuracy and speed of water jet cutter

The water cutting machine is finished by using the ultra-high pressure technology. It only needs to pressurize the ordinary tap water to the pressure of 250-400mpa, and then radiate it through the gem nozzle with the inner hole diameter of about 0.15-0.35mm...

How to treat each part in water cutting

The water supply system needs to be equipped in the water cutting machine, and in order to prevent water leakage when the pipeline is connected, the thread of the steel pipe head must be more than three teeth higher than the screw pad...

Which parts can be the core of the water jet

When you need to measure the quality of a piece of equipment, you will generally turn your eyes to the core components of the equipment, as is the case with water cutters. What are the core parts of the water jet? What are the requirements for meeting the standards...

Study on improving electrode efficiency of water cutting

Try to use new emulsion during processing. When choosing emulsion oil, it is better to choose DX-3 type wire cutting emulsion oil or DX-4 type wire cutting working fluid. The impurities in the old emulsion are difficult to filter out, while the copper material is soft...

Selection of electrical parameters for water cutting

The selection of electrical parameters is a key point in the process of water cutting, which mainly includes the determination of processing current, voltage, pulse width, duty cycle and other parameters...